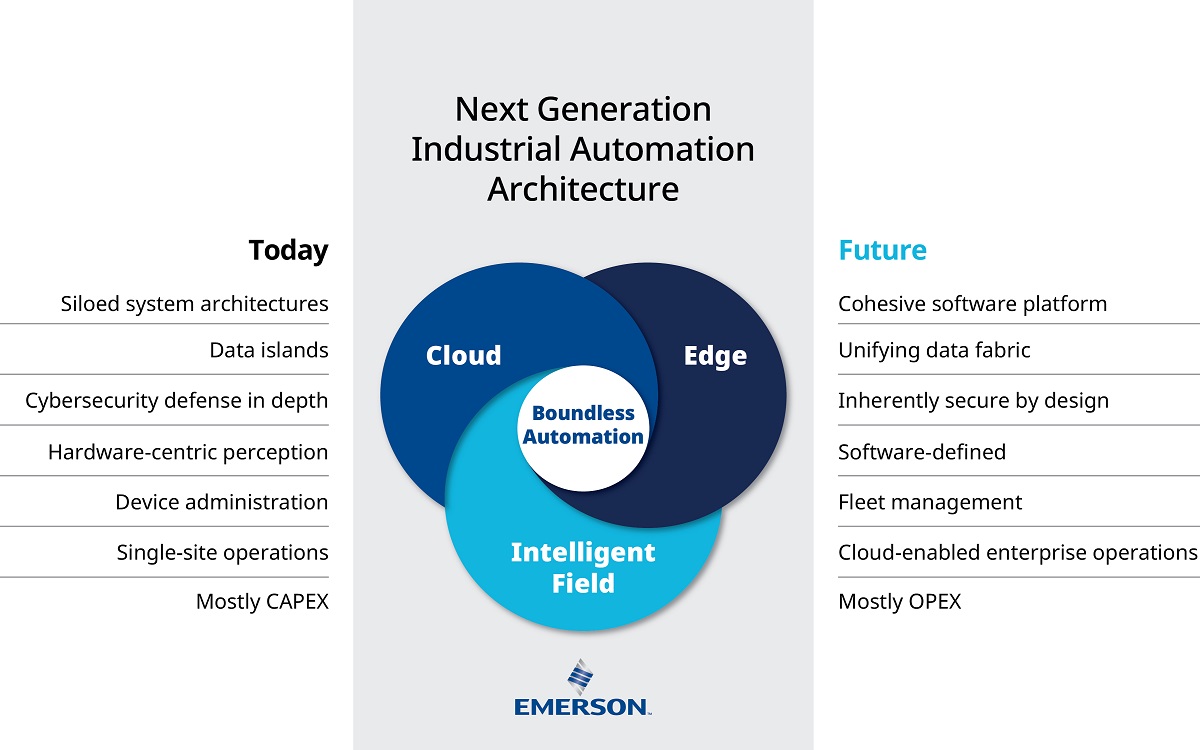

Global technology and software company Emerson (NYSE: EMR) is poised to transform industrial manufacturing with the next-generation automation architecture: Boundless Automation™ aims to break down data silos, liberate data and unleash the power of software.

As many companies wrestle to extract full value from their digital transformation efforts, the limitations of today’s automation architecture are being realized. Technology stacks built around each functional department – production, reliability, safety and most recently sustainability – have resulted in islands of fragmented data, which are proving difficult to integrate or use. As a result, new business insights promised by digital transformation remain elusive.

Blueprint for a modern industrial computing environment

To address this challenge and help customers achieve their operational improvements, Emerson is introducing a vision and actionable strategy. Emerson wants to push more computing power closest to where it’s needed and establish the blueprint for a modern industrial computing environment. This environment includes flexibility to deploy software across the intelligent field; a modern, software-defined edge; and the cloud. All three domains will be connected through a unifying data fabric, helping to maintain data context, improve its usability and increase security.

“After decades of implementing evolving automation strategies, manufacturers recognize the need to extract greater value from data that is locked in a rigid and now outdated automation architecture,” said Emerson President and CEO Lal Karsanbhai. “The proliferation of data and the development of advanced software are moving us to an era of unprecedented productivity. Rich data and advanced software are converging to form the next major inflection point in the industry.”

Karsanbhai addressed industry leaders in Düsseldorf at Emerson Exchange EMEA 2024, a conference for customers in chemical, life sciences, metals and mining, power, hydrogen, biofuels, carbon capture and energy industries.

Democratizing and contextualizing data

Emerson’s modern, software-defined automation architecture will break down hierarchical networks, securely democratizing and contextualizing data for both people and the artificial intelligence (AI) engines that depend on a continuous flow of information. Emerson continues to innovate its broad portfolio of technologies in development to serve as the foundation for the future of Boundless Automation.

“With an industry-leading technology stack and decades of proven expertise, Emerson is uniquely positioned to engineer and deploy automation to maximize customers’ technology investments and deliver measurable performance improvements,” Karsanbhai said.

Boundless Automation unifies disparate systems

Emerson’s Boundless Automation architecture will break down barriers and data silos across the intelligent field, edge and cloud. Integrating these disparate systems with a unifying data fabric will offer new insights and help companies optimize operations across production, reliability, safety, sustainability and its workforce.

Intelligent Field:

An intelligent field will simplify access to more data from more sources and a greater diversity of applications. With smarter devices and new connection technologies like 5G and APL, customers can streamline both connectivity from anywhere in the world, and integration across the new architecture.

Edge:

The new OT edge creates a modern, secure, low-latency computing environment, putting new software tools and actionable data closest to its user. This enhanced edge environment establishes a platform for IT and OT colleagues to innovate and collaborate more than ever before.

Cloud:

The cloud will power complex operations and engineering capabilities on-premise and across the enterprise by providing infinite analytical computing power, enterprise collaboration, attractive lifecycle costs and on-demand support and service.

For more information on the innovations and technologies supporting the new Boundless Automation architecture click here.